Artificial Intelligence in the Manufacturing Sector

Discover how AI-powered manufacturing software solutions are transforming production facilities. With our solutions, manufacturers can easily integrate advanced computer vision models into existing workflows with flexible deployment options. This technology harnesses the power of AI for quality control, helping teams identify defects faster, ensure compliance, and optimize inspection processes at every stage.

Quality Control

Quickly detect and flag defects at key quality control points throughout the entire production process. You can customize your computer vision model to classify components as 'Good/Not Good' or to identify more specific issues such as 'Missing Part,' 'Scratch,' 'Burr,' and more. This is a key application of computer vision in manufacturing, enhancing quality control with greater speed and accuracy.

Inspection and Assembly

Efficiently detect missing components, incorrect component placement, misalignment, welding defects, uniform application of sealants and adhesives, and cosmetic defects. These are some of the most common production challenges addressed by our AI-based computer vision solutions, helping teams improve precision on the assembly line.

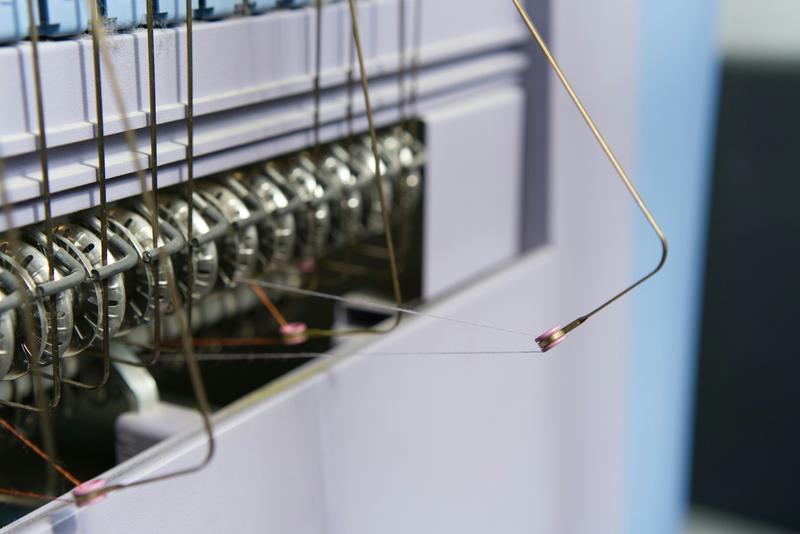

Textile Quality Control

You can train models to inspect textile materials for defects such as stains, tears, weaving or knitting irregularities, and color inconsistencies.

Workplace Safety

With our solutions, you can actively monitor employee behavior to ensure compliance with regulations and the proper use of safety equipment.

The Benefits of Adopting Computer Vision and AI in Manufacturing

-

Streamline Production

- With computer vision, you can instantly identify issues or defects on your production line, enabling timely interventions to reduce costs and waste.

-

Boost Productivity

- Automatic monitoring can significantly increase the productivity of your industrial facilities.

-

Enhance Operational Compliance

- Computer vision ensures your team follows operational procedures consistently across all facilities.

-

Optimize Resources

- By collecting data on your production processes, you can identify bottlenecks and optimize resource allocation.